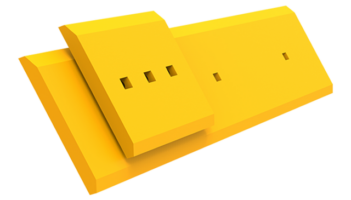

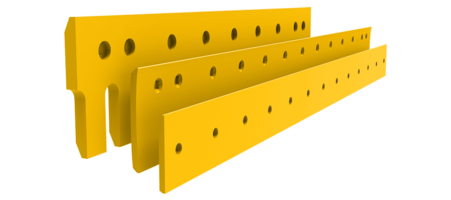

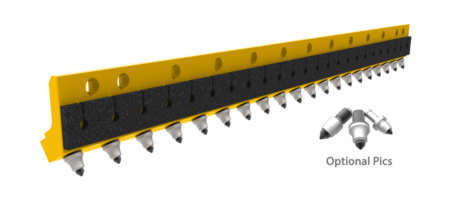

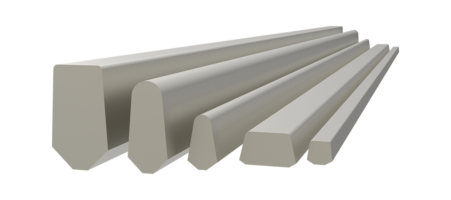

Rolled Steel Cutting Edges

Hensley offers an extensive line of blades and end bits for all makes and models of dozers, graders, and loaders. Blades and end bits are fabricated using through-hardened carbon steel to exacting specifications that meet the demanding needs of earth moving applications. Hensley blades and accessories are engineered to deliver maximum performance and long lifespan at an affordable cost.

Machine Types:

- Dozers

- Loaders

- Graders

Hensley Construction Brochure