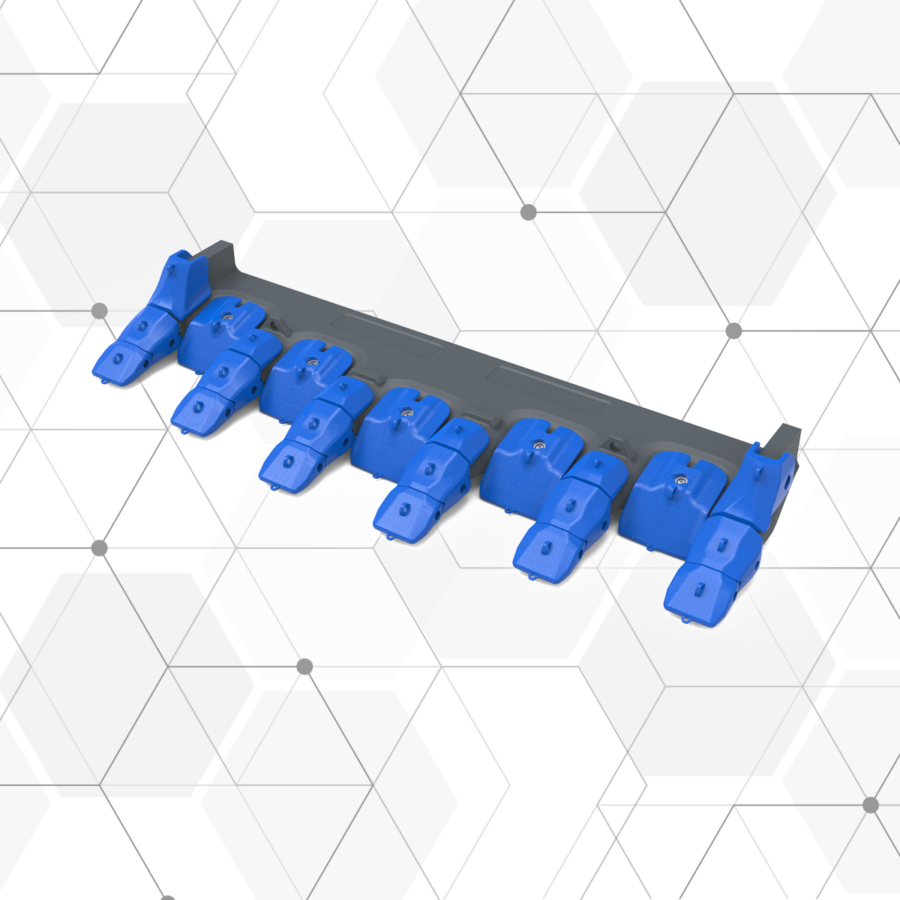

The new GETpro Cast Lip System provides end users a custom fit solution for the latest generation of surface mining excavators. The cast lip is designed to work with maximum efficiency with a new 3 piece tooth system and new shroud that have been completely redesigned, enhancing the lifespan of the lip while significantly reducing the total weight. The wear package is designed to provide substantial improvements in penetration, shovel loading efficiency, and component wear life. The fastening system has been redesigned for mechanically attached components to provide reliable retainment and improved change-out times. As a complete package the new GETpro Cast Lip System offers end users a unique solution to improve their total cost of ownership and running cost per ton.